REBUILDING

The Rebuilding area is situated in the main barn and utilizes the Hoist and 1 or 2 rotisseries as required.

We have encountered several negative issues associated with the knowledge and technology of the era in which the cars were originally built. We have subsequently arrived at solutions which allows for the original character and pleasure of the car to be retained but removing the concerns of driving an older vehicle.

STARTING

Memory Lane Classics 948cc frogeye engines start immediately at the pull of the button but still have the nostalgic sound of the original motor.

BODYWORK

The shell is painted in the original manufacturing colours preserving the vehicle in all its glory for years to come.

GEARBOX

The box is rebuilt with later specification which gives the look of the traditional gearbox with better performance.

ENGINES

When the engine comes back to us from Ivor Searle the engines are firstly fitted to our test rig and built up with new components.

LUBRICATION

We have formed an allegiance with Duckhams classic motor oils and will only utilize their lubricants in our restoration projects.

SCREENS

The windscreens are stripped, the glass is recycled and re-chromed dependent upon the year of manufacture.

INTERIOR

All moving parts are cleaned, powdered coated and refitted. New carpets are fitted including the boot area.

CHROMEWORK

All original chrome component are completely stripped, examined, repaired where necessary and re-chromed.

LIGHTS

The headlights are upgraded to sealed unit halogen specification which gives a much improved performance.

BRAKES

We have decided to keep the original drum brakes, we believe that these brakes set correctly they will offer sufficient stopping power.

WIRING LOOM

The wiring loom is removed, scrapped and replaced with an upgraded system to marry into the new electronics system.

REAR AXLE

The rear axle is completely stripped; the gearing in the differential is removed, stripped, cleaned, repaired or replaced as required.

REAR SPRING

We have researched in great depth the quality of the springs currently available on the market.

STARTING

Batteries were traditionally positive earth and were charged using a dynamo, which would typically charge at about 15-16 amps whereas an alternator is much more efficient and charges at about 45 amps.

The fuel pumps were mechanically driven, drawing the fuel from the petrol tank in the rear sending it to the carburetors at the front. The issue being that by the time the fuel has arrives at the carburetors the battery is usually on its last legs. If the car starts it then has to be driven for many miles for the dynamo to recharge the battery sufficiently enough for the next breath-bating encounter when attempting to start the engine.

OUR SOLUTION

1. Larger capacity battery converted to negative earth.

2. Alternator in the guise of a dynamo

3. The mechanical fuel pump is removed and replaced with an electric fuel pump

The fuel tank is replaced with a new one as are all fuel lines.

4. The correct 1 1/8 inch H1 SU carburetors are fitted, which historically require fuel to be delivered at approx. 3-4 psi. Electric fuel pumps deliver fuel at 7 psi so an inline filter/regulator is fitted to ensure any residue from the fuel is filtered out and the fuel supply is then regulated to precisely the psi requirement of the carburetors. The original H1 SU carburetors are re-engineered by a UK prominent carburetor specialist who strip and clean them before re assembling with new components. The carburetors are re-calibrated back to the original factory settings, thus giving us a better than new set of original carburetors.

5. New spark plugs correctly set are installed and the old points system is replaced with electronic ignition. All this guarantees that a correct flow of fuel and a strong spark will be delivered to the chamber at precisely the right moment.

Memory Lane Classics 948cc frogeye engines start immediately at the pull of the button but still have the nostalgic sound of the original motor.

BODYWORK

1950’s British motor cars were poorly assembled and poorly painted leaving unprotected areas of the bodywork where rust and corrosion can quickly take hold. We have stripped all the paint, repaired the bodies to better than original condition and found and eliminated the design faults of the original manufacturing. We powder coat the entire body shell which is then baked on. The shell is painted in the original manufacturing colours preserving the vehicle in all its glory for years to come.

GEARBOX

The original smooth case gearbox was notoriously clunky and temperamental when travelling through the gears. The later generation gearboxes are much smoother and allow for much easier gear changing.

OUR SOLUTION

We remove all the gearing from inside the smooth case, we completely clean and preserve the box. The box is then rebuilt with later specification gearing which gives the look of the traditional gearbox with the performance of the later, better models.

ENGINES

These engines are now 60 years old and usually extremely tired (not that they were particularly brilliant when they originally left the factory). We, having originally utilized the services of an engineering workshop to re-skim, re-grind, re-place where required all components: have subsequently entrusted this task to a nationally acclaimed engine rebuilder (Ivor Searle ltd of Cambridge) link to website who not only completely re-engineer and rebuild these engines to an exacting standard but also offer a 12 month warrantee which we will pass on to the new owner.

When the engine comes back to us from Ivor Searle the engines are firstly fitted to our test rig (as previously described) and built up with new components, water pump, starter motor and alternator, carboretors etc and tested prior to installation and fitting into the vehicle.

When the engine is installed a new stainless steel exhaust is fitted.

LUBRICATION

Back in the day, Duckhams was the go to oil brand for all the would-be motoring enthusiast who spent most of their weekends tinkering with their beloved motor cars. We have formed an allegiance with Duckhams classic motor oils and will only utilize their lubricants in our restoration projects.

We grew up in the sure knowledge that when you ran your finger along the dipstick and the oil was green on your fingers; the engine was in safe hands.

Duckhams are currently developing new machinery, which analyzes oil samples to confirm engine quality. This is an exciting development, which in the very near future will be offered to all memory lane classics customers – WATCH THIS SPACE!!

Duckhams have awarded memory Lane Classics with distributorship for their products, which we are honored to hold and treasure dearly.

SCREENS

The windscreens are stripped, the glass is recycled, the surrounds are polished, re-chromed or re-anodized dependent upon the year of manufacture and nature of the original product used. They are then fitted with new glass.

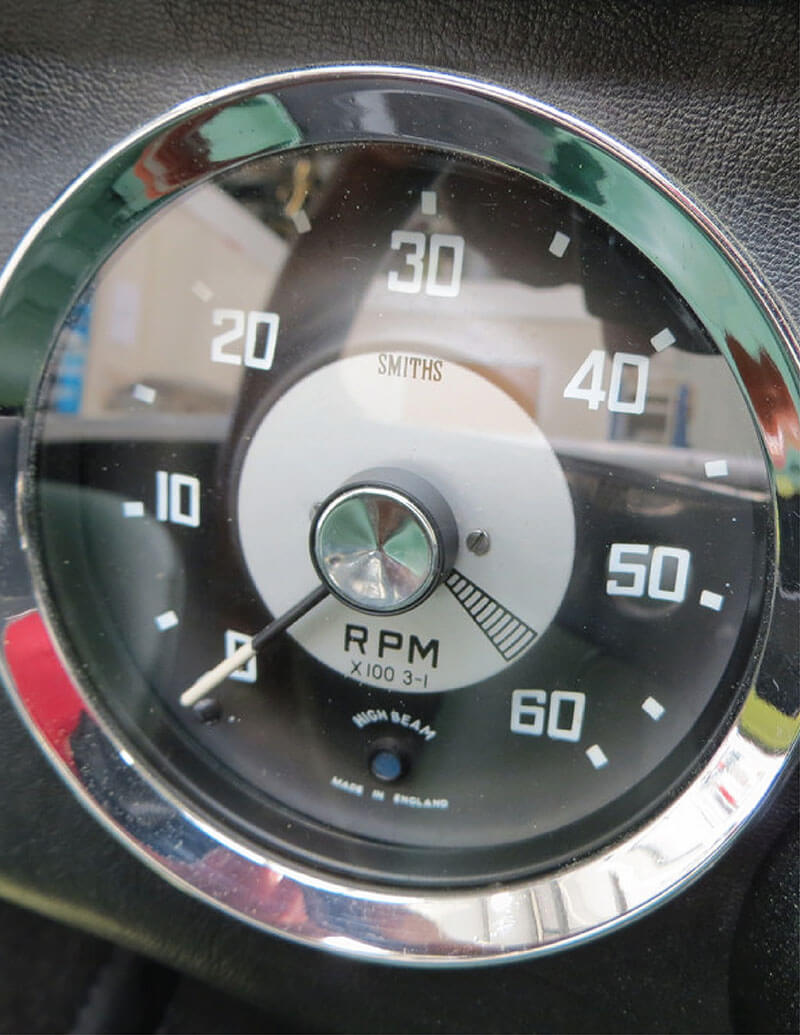

INTERIOR

All seats are stripped back to the frame, all soft materials are disguarded, the frame and the base are cleaned, repaired and powder coated then rebuilt utilising new foam and leather seat facings. All moving parts are cleaned, powdered coated and refitted. New carpets are fitted including the boot area. The dashboard is completely stripped, cleaned powder coated and recovered in the original coloured material. The gauges are sent away to a UK acknowledged gauge restorer to be re-engineered and re-calibrated before having the faces reprinted, the surrounds re-chromed and the glass replaced.

CHROMEWORK

All original chrome component are completely stripped, examined, repaired where necessary and re-chromed to better then the original specification.

LIGHTS

The headlights are upgraded to sealed unit halogen specification which gives a much improved performance, as apposed to the original peering through the gloom experience. You can now be confident the lights can be used without draining the battery all thanks to the new electrics!!

You’re welcome!!

All other lighting components have been left to the original specification.

BRAKES

After much deliberation we have decided to keep the original drum brakes, as we believe that when these brakes are set correctly they will offer sufficient stopping power, which is true to the original specification. However, it would be an easy task to convert these brakes to disc, which could be done upon customer request. However given the lightness of a frogeye sprite, consideration needs to be given to the efficiency of the braking system, as this could result in a Johnny English style passenger exodus from the vehicle.

WIRING LOOM

The wiring loom is removed, scrapped and replaced with an upgraded system to marry into the new electronics system. This includes a new coil, fuse box etc.

REAR AXLE

The rear axle is completely stripped; the gearing in the differential is removed, stripped, cleaned, repaired or replaced as required, re-greased and re-packed. The differential housing is powder coated with a chrome finish. The prop shaft is removed, cleaned and powder coated. The universal joints are removed and replaced with new.

REAR SPRING

We have researched in great depth the quality of the springs currently available on the market. It was not felt that the original springs of 60 years vintage could be trusted to deliver the safe ride experience required. We have identified the differences in ride height and compliance and selected the best option for a safe predictable ride, good handling characteristics and consistency. Proudly, the best springs we found were British and manufactured in Yorkshire!!